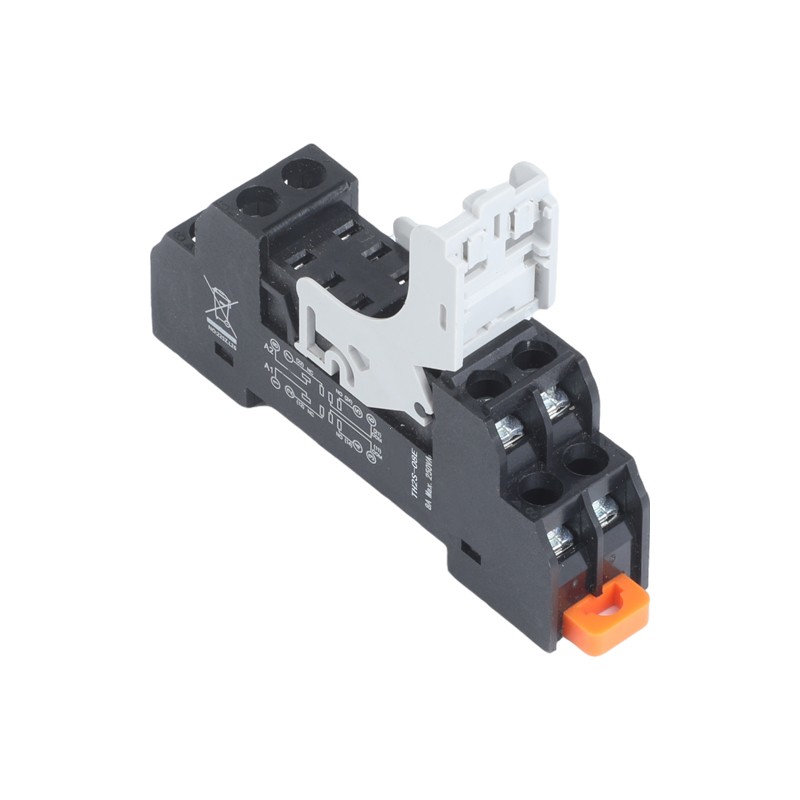

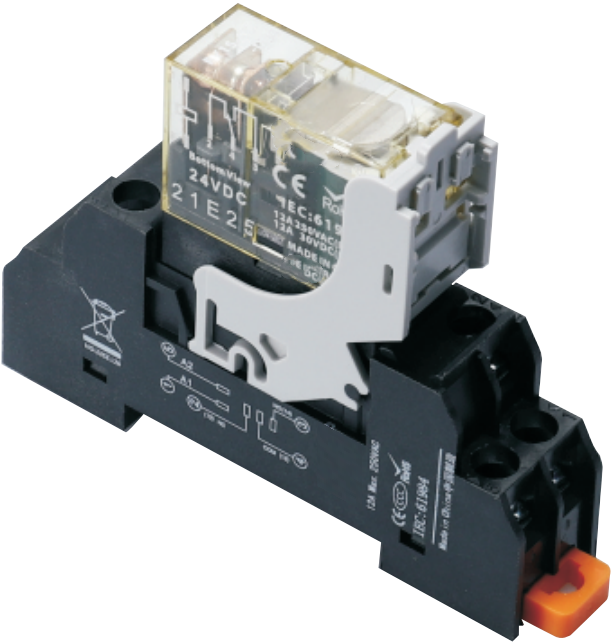

Taihua narrow type power relay SSR Plc module TH2S-08E

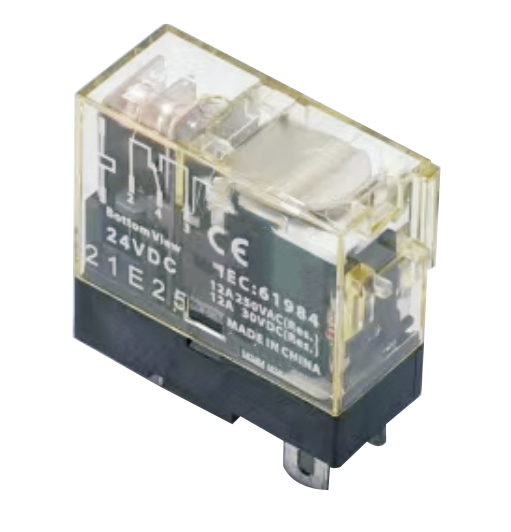

The contact is thickened to ensure it can support large currents while still maintaining excellent conductivity. Additionally, the moving contact sheet material is imported FCNP-C17200 copper, which is quenched with super elasticity and high-frequency working control without overheating.Another feature that enhances the reliability of the TH2S-08E is its plastic buckle. The relay module comes equipped with a locking function that makes it more sturdy and can withstand harsh environmental conditions. Additionally, the module also has a built-in label that can be used to mark the corresponding circuits, making it easier for engineers to identify and manage the module.Finally, this relay module adopts copper feet, which enhance the contact conductivity and reduce the resistance value. The process of first plating and then punching and integrating with the mold ensures that the contact and foot position synchronize without deformation. This feature ensures that the relay module operates efficiently and reliably, minimizing the need for maintenance.In conclusion, the Taihua TH2S-08E narrow type power relay PLC module is an innovative and high-performance electronic component designed for various applications. Its advanced features like full copper coil, LED indicator light, and contact material make it a reliable and efficient solution in harsh industrial environments. Its plastic buckle and copper feet enhance its durability and reliability, making it an ideal choice for automation and control systems.

● Small size, high sensitivity, and large current

● Load capacity of 1Z 12A; 2Z 8A

● Equipped with LED surface mount indicator

● Equipped with mechanical indicator window

● Taihua industrial control relay is widely used in PLC, CNC machine tool distribution box, robots, intelligent manufacturing and other control systems for output signals and safety drives. It is the best choice for remote control, production, packaging, transportation, inspection, warehousing, and all kinds of equipment and product automated assembly lines.

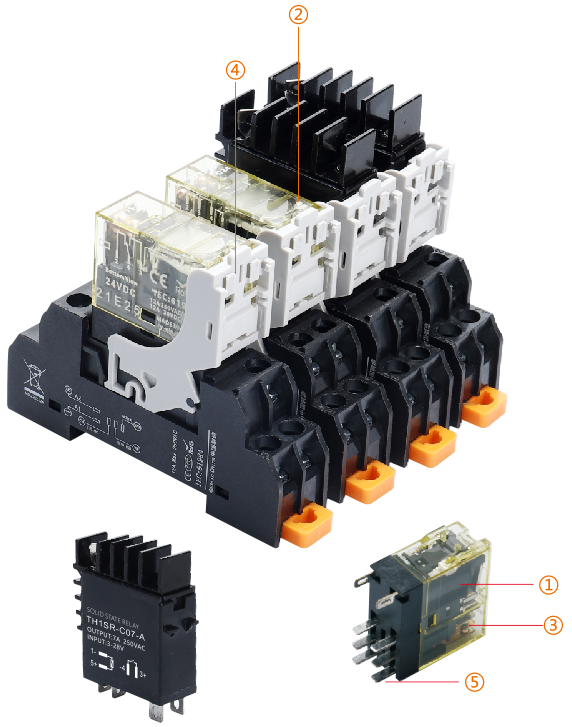

①Full copper coil:

Adopts high standard turn-to-turn electromagnetic coil with stable current, heat resistance, better heat dissipation, reliable suction, and long service life.

②LED indicator light:

Adopts LED indicator light with long service life. Red indicates AC coil, green indicates DC coil.

③Contact material:

Adopts silver oxide tin steel with silver layer thickness of 0.4mm. The contact is thickened to support large current. The moving contact sheet material is imported FCNP-C17200 copper, which is quenched with super elasticity and high frequency working control without overheating.

④Plastic buckle:

Equipped with a locking function to make the relay more sturdy. It has a built-in label to mark the corresponding circuits.

⑤Adopts copper feet:

The copper material enhances the contact conductivity and reduces the resistance value. The process of first plating and then punching and integrating with the mold ensures that the contact and foot position synchronize without deformation.

| Modality | 1NO/NC | 2NO/NC |

| Load | 12A 250VAC | 8A 250VAC |

| Resistance | 12A 250VAC/30VDC | 8A 250VAC |

| Contact Res. | ≤50mΩ | |

| Insulation Res. | ≥500MΩ | |

| Pull-in Voltage | DC: ≤75% (rated voltage);AC: ≤80% (rated voltage) (23℃) | |

| Release Voltage | DC: ≥10% (rated voltage);AC: ≥30% (rated voltage) (23℃) | |

| Max.Voltage | 110% of rated voltage (23℃) | |

| Pick-up Time | ≤20ms | |

| Release Time | ≤10ms | |

| Coil Power | About 0.53W(DC) /about 0.9VA(AC) | |

| Electrical Life

Switching frequency 720Ops/h

|

At room temperature, 5A 250V/30VDC (1s on, 9s off ) : ≥400000 times | |

| At 70℃,5A 250V/30VDC (1s on, 9s off ): ≥200000 times | ||

| At room temperature, 7A 250V/30VDC (1s on, 9s off ) : :≥100000 times | ||

| At 70℃,7A 250V/30VDC (1s on, 9s off )::≥50000 times | ||

| At room temperature, 12A 250V/30VDC (1s on, 9s off ) :≥50000 times | ||

| At 70℃,12A 250V/30VDC (1s on, 9s off ): :≥30000 times | ||

| Mechanical Life | ≥20000000times(18000 Ops/h)(refer to GB/T14048.5) | |

| Electrical strength | Between same-level contacts: 1000VAC, 50Hz, 1 min (leakage current 1mA) | |

| Between different-level contacts: 2000VAC, 50Hz, 1 min (leakage current 1mA | ||

| Between contacts and coil: 2000VAC, 50Hz, 1 min (leakage current 1mA) | ||

| Minimum Touch Current | 3V AC/DC, 5mA (reference value, depending on environment and load conditions) | |

| Vibration Res. | XYZ axis, 60Hz, 2mm amplitude, 10 hours (observed every two hours) | |

| Fall Prevention | Can withstand a vertical drop from 1 meter to the ground for 3 times and function normally | |

| Package Drop | Can withstand consecutive drops from a height of 1000mm for 4 times without damage | |

| Temperature Rise Test |

In accordance with clause 8.3.3.3 of GB/T14048.5 standard (at a constant temperature of 23°C, with all contacts at full load for 60 min, and temperature difference before and after the test not exceeding 55K within a one-hour interval) |

|

★ All the above parameters and specifications are established based on the internal experimental data standard of Zhejiang Taihua Company, and the company reserves the right of final interpretation

| Performance Parameters | ||

| Salt Spray Test | 24h for one cycle (refer to GB/T2423.18-2012) | |

| Low Temperature Test | -40°C,96h,contact resistance≤200mΩ、pressure change value≤30%,LED normal | |

| High Temperature Test | 80°C,96h,contact resistance≤200mΩ、pressure change value≤30%,LED normal | |

| High&Low Temperature impact Test(Include Accelerated aging test with LED lights) | -40°C~+85°C at 85% RH, 40 minutes/cycle for 50 cycles, contact resistance ≤200mΩ, pressure change ≤30%, LED normal | |

| Working environment temperature | -40°C~+70°C,non-vacuum state, no freezing | |

| Working environment humidity | 35~85%RH | |

| Working storage temperature | Packaging intact , -40°C~+55°C | |

| Working storage humidity | Packaging intact ,45~90%RH | |

| LED Parameter | Rated current≤10mA | |

| The lamp bead type is a surface-mount non-polar double-chip LED | ||

| voltage-reducing method: built-in voltage-reducing resistor; Life≥50000h (reference value) | ||

| CERT | CCC CE ROHS REACH(customized) | |

| QA | 24 months | |

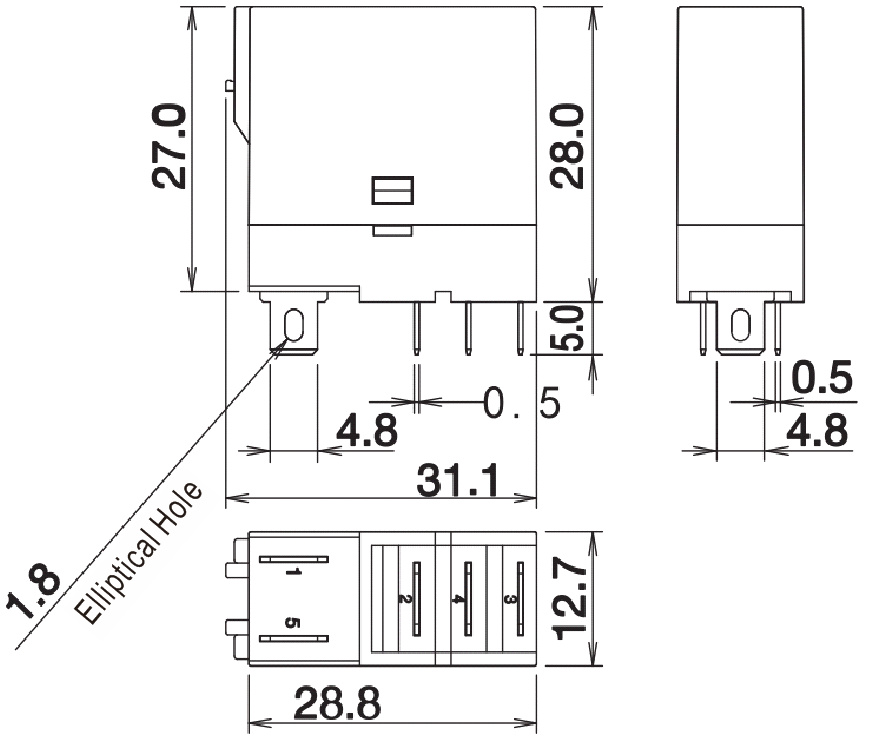

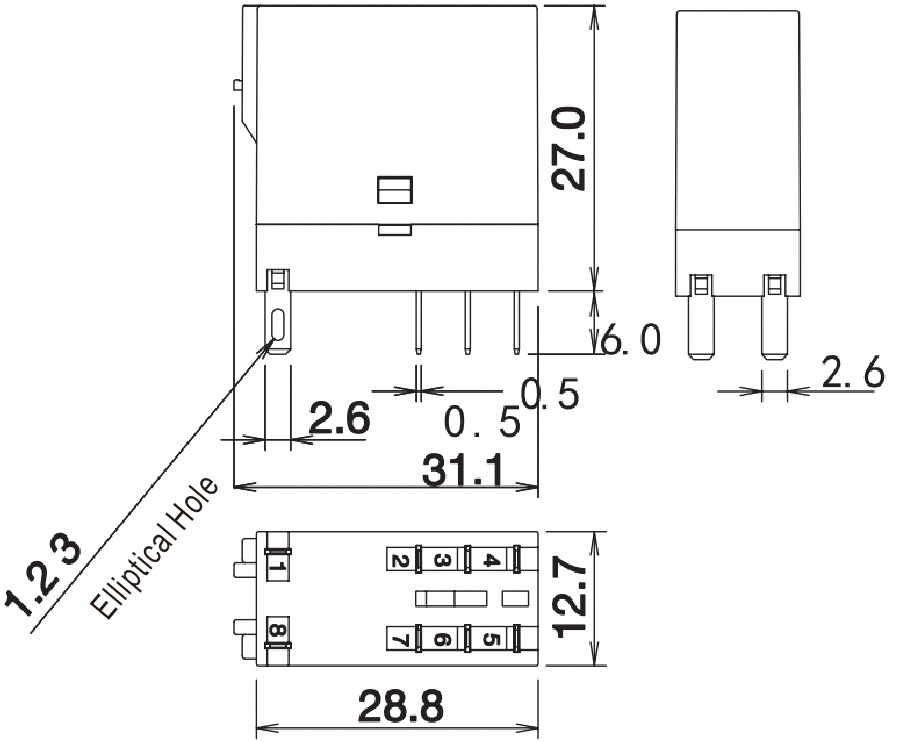

| The tolerance not indicated on the drawing | Executed according to GB/T1804-m standard | |

| Pack&size | 2822 blister pack:10pcs/box, box size: 21.5*13*5.5CM | |

| Net Weight | DC24V:19.5g;AC230V:21.2g | DC24V:18.9g;AC230V:19.8g |

| Coil Specification | |||||||

| Rated Voltage V.DC |

6 |

12 |

24 |

48 |

110 |

220 |

|

| Coil Resistance Ω |

40 |

180 |

640 |

2600 |

13000 |

42000 |

|

| Rated Voltage V.AC |

6 |

12 |

24 |

48 |

110 |

230 |

380 |

| Coil Resistance Ω |

11.5 |

180 |

370 |

640 |

4430 |

16500 |

42000 |

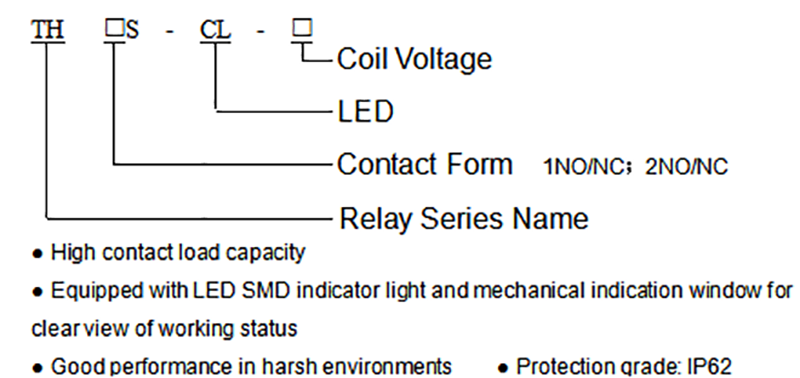

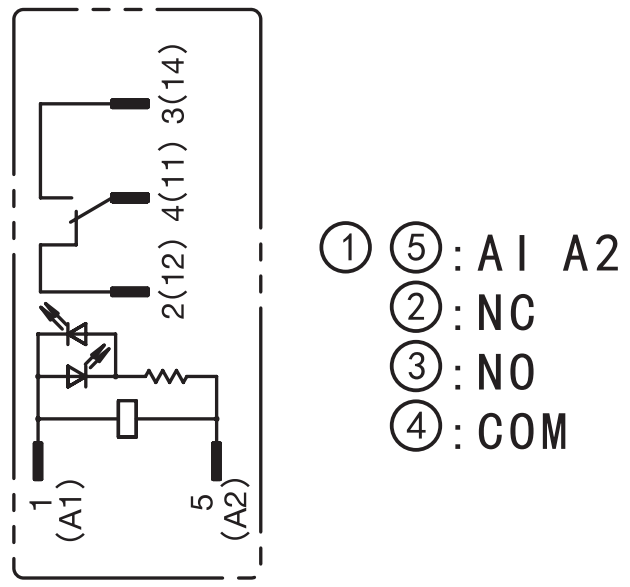

TH1S

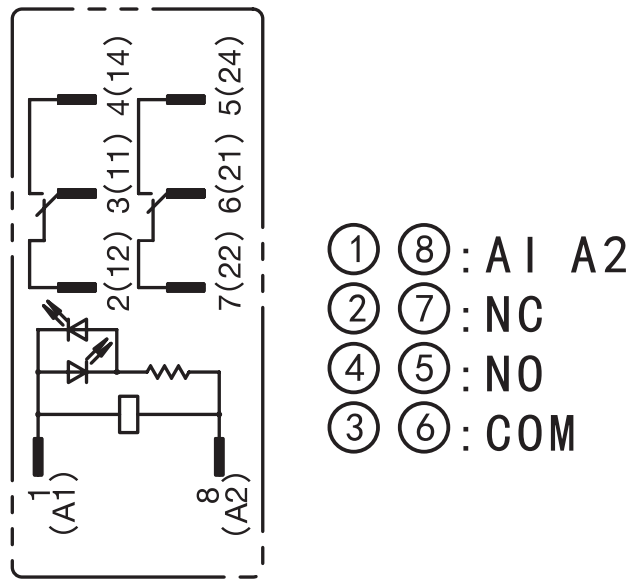

TH2S

TH1S

TH2S